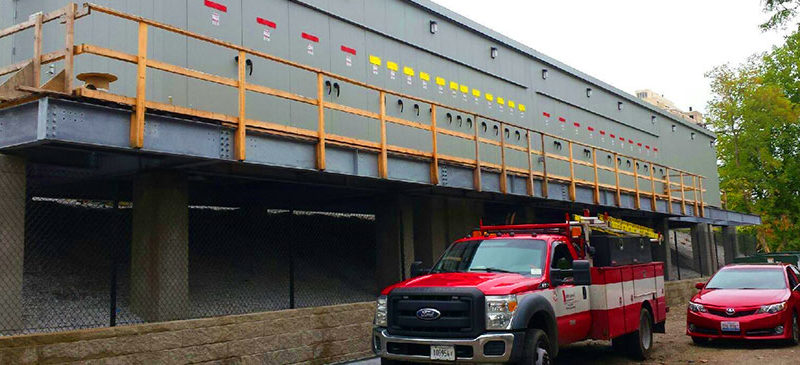

Project Description

Client: Metra

Location: Chicago, Illinois

Year Completed: December 2007

Contract Value: $1,450,000

The Challenges

- Demolition of existing pedestrian bridge at Metra Electric Station.

- Replacement of approximately 210’ long pedestrian bridge accessing Metra station platform.

- Installation of micro piles drilled into bedrock for new bridge support foundations.

- Original schedule called for removal of existing bridge and erection of new bridge over three weekend overnight periods. The work was completed in two weekend overnight periods.